The Merrimac Hat Corporation

A brief history with some photographs from The Bartlett Museum collection.

The Merrimac Hat Corporation was founded in Amesbury and operated from the 1850s until 1971. They had multiple locations in Amesbury as well as West Upton, MA, Greenville, AL and Beacon, NY. Merrimac Hat Corporation hats are displayed at the Bartlett Museum and the Amesbury Hat Museum located in the Whittier Home in Amesbury. The Amesbury Carriage Museum also has a collection of photographs and additional information about the company.

Abner L. Bailey, founder of the Merrimac Hat Corporation

The most well known location in Amesbury was on the Merrimac River, but MHC also had a location on Cedar Street. These buildings still exist today in Amesbury, and are now condos, apartments and artist/studio space.

The Cedar Street location of the Merrimac Hat Corporation. This location made fur hats.

This old postcard shows the Merrimac River location of the MHC. This is now the location of Hatter’s Point condominiums on Merrimack St./Pleasant Valley Rd.

The MHC Factory in Greenville, Alabama. There were 5 buildings: Main building, Dye House, Storehouse & Machine Shop, Boiler House and Cafeteria

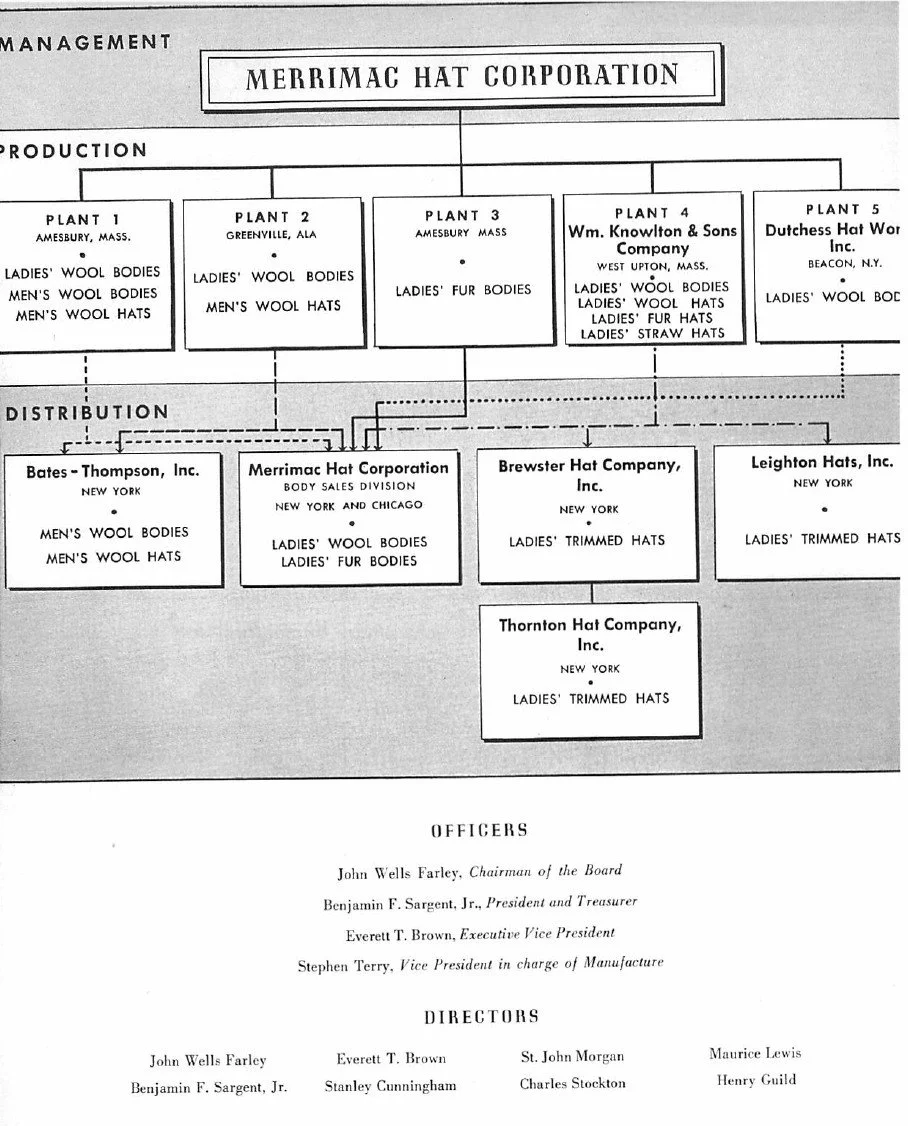

This chart is from a 1944 MHC publication and shows various manufacturing and distribution locations, as well as the company officers and directors.

This was one of the entrances at Cedar Street.

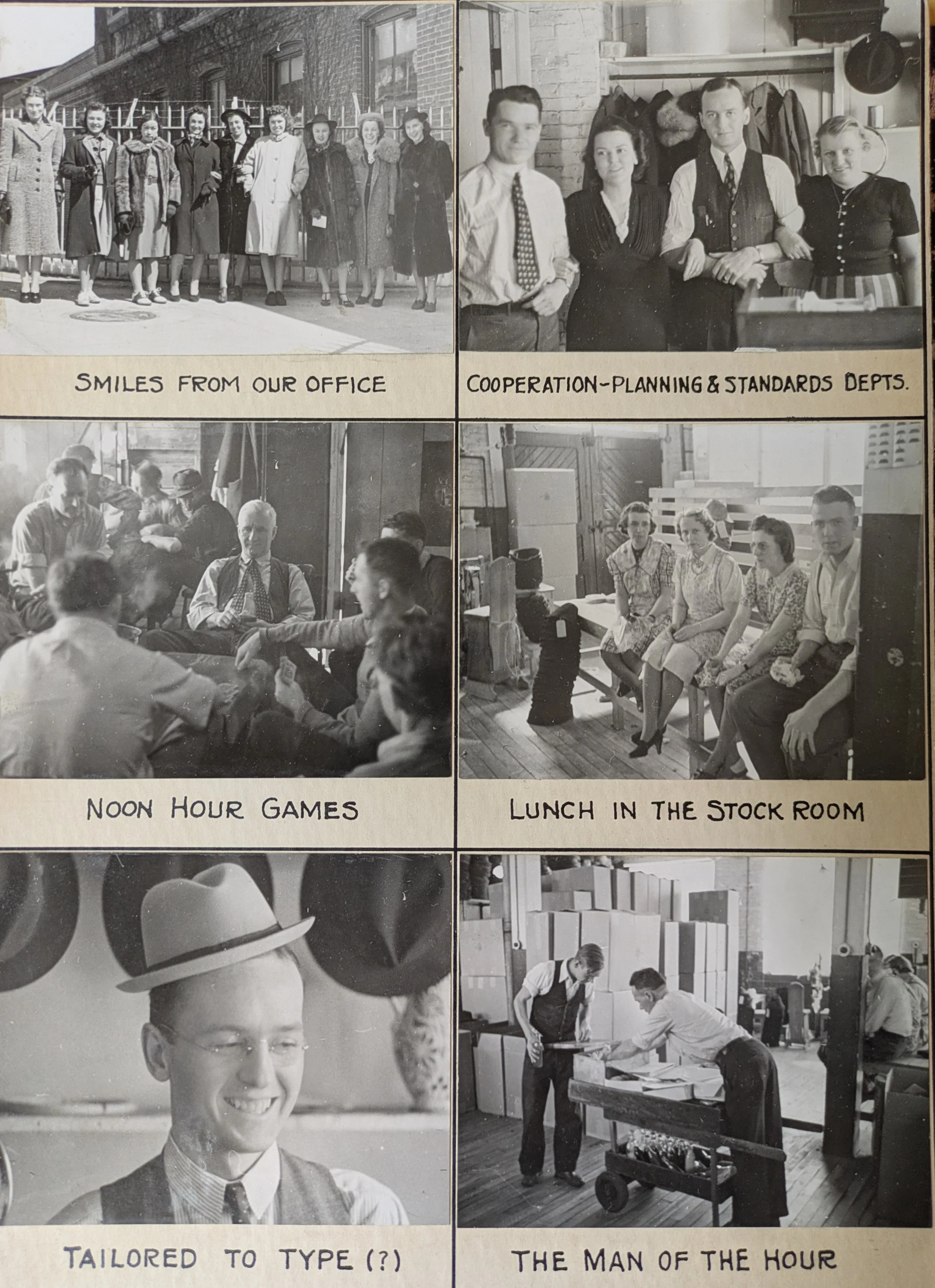

MHC had a quarterly magazine. These photos are from April, 1939, the Volume 1, No. 2 issue

During World War 2 the company made mosquito netting for the military.

Hawley Patten (Personnel & Purchasing) and Hans Rie (President) of MHC. You can see Hans Rie’s parking spot in the image above showing the employee entrance.

A worker prepares rabbit fur for mixing and blowing, prior to the forming operation in the Cedar St plant

The wool carding room at Plant #1, Merrimack St.

David “Red” Taylor checks in with a worker in the Forming Room at Cedar St.

The “Blacking” Department, blacking machine in foreground.

The men’s hat blocking process, at the Merrimack St. plant

Forman Arthur Roberts works on a hat at Cedar St.

A worker at the coning machine in the Cedar St. plant. The fur body is on the cone and the operator is about to cover it with wet burlap.

The Velouring Department at Plant 3, Cedar St. Several workers are “clipping” blank fur felt hat bodies. This was piece work for the workers who would get a price for each dozen hat bodies.

This process step was called ‘pouncing’, which removed the rough nap.

An expert trimmer finishes an Upton hat.

A vast variety of ladies Upton hat samples at the Merrimack St plant

The finished product! These pictures are from Merrimac Hat Corporation brochures, and show advertisements from Vogue and Harpers Bazaar

These are only a few of the photographs in our collection. Please contact us if you have any family connections to the Merrimac Hat Corporation or want to do additional research.